Weidong Zhang received the B.S. degree in automation and Ph.D. degree in control science and engineering from University of Science and Technology Beijing, Beijing, China, in 1996 and 2004, respectively. Professor Weidong Zhang is the vice President of University of Science and technology Beijing, Beijing, China. His research interest include monitoring and detection technology and data governance, multimodal fusion and deep mining, cross-scale digital twin and remaining life prediction. He has presided more than 20 projects from NSC, 863 Plan, etc. and won 3 awards of science and technology at the provincial and ministerial level. He has published more than 90 papers and holds 15 patents. Dr. Zhang is a member of INFORMS, TMS and Chinese Society for Metals ( CSM).

- Project 1: Major Infrastructure Construction Projects of Science and Technology, Major Engineering Materials Service Safety Assessment Facilities, 2007-2022

- Project 2: Key Plan Project of HBIS Group, Research on Continuous Casting Process Quality Improvement Based on Hybrid Modeling and Intelligent Optimization, 2023-0370, 2022-2024

- Project 3:Enterprise Research Project, Research and Development of Visual Detection Model for Characteristic Markers in the Steel Industry Based on Deep Learning, 2023-2024

- Project 4: Innovation Team Project of Southern Marine Science and Engineering Guangdong Laboratory, Cross-Scale Service Safety Evaluation and Digital Model of Marine Titanium Alloy Materials and Equipment, 2021-2023

- Contribution 1:Cross-scale Service Cross-scale Digital Twin and Remaining Life Prediction

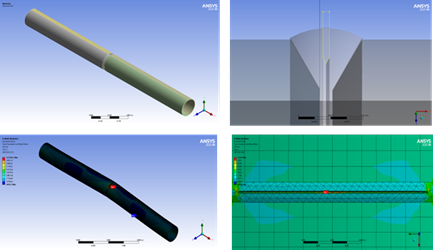

Aiming at the problem that environmental sequence parameters caused by uncertainties and randomness in the material failure process cannot be corresponded to the mechanism model, digital twin technology is introduced. Monitoring data is used to update failure prediction data, realizing a point to point real time visualization process of multi-dimensional information of the material failure process in the digital twin model.

The cross-scale service evaluation method of structural materials converts the structure simulation results at the macroscopic scale with the test data at the micro-mesoscopic scale, and comprehensively considers the mechanical properties and failure mechanisms at different scales to more accurately evaluate the performance and remaining life prediction of the structural materials in the actual service process.

-Contribution 2: Intelligent Management and Control of Process Qualify

Process quality is a core indicator in industrial production. However, in industrial production, quality control is often challenging, with a complex process, numerous parameters, and strong timeliness. Take steel continuous casting production as an example. we conduct data governance of the continuous casting process, develop a hybrid model based on mechanism and data - driven approaches, optimize process parameters using data statistics and artificial intelligence algorithms, carry out quality analysis with the help of large - language models, fully explore data value, and achieve intelligent control of continuous casting.

- Contribution 3:Multi-dimensional and Multi-modal Data Fusion Analysis of Targets.

Based on general object detection, we conducted research on multi-dimensional and multi-modal object detection to address the challenges of detecting objects with large dimensional variations, high density, and difficulties. We conducted research on multi-dimensional object detection to address the challenges of detecting dense and weak objects, and made designs and innovations at the data level, feature level, and model level.

1. Cheng Zhou, Kaibo Liu, Weidong Zhang, Jianjun Shi, “An Automatic Process Monitoring Method Using Recurrence Plot in Progressive Stamping Processes”, IEEE Transactions on Automation Science and Engineering, 2016, 13(2):1102-1111.

2. Ai Yibo, Wang Fan, Sun Chang, Zhang Weidong. Performance Degradation Analysis and Life Prediction of the Fatigue Damage Process of High Strength Aluminum Alloy Using Acoustic Emission[J]. Journal of Nondestructive Evaluation. 2021,40(43):1 - 12.

3. Ai Y, Ma N, Zhang T, et al. A new mean value of failure criteria updated compensation method based on heuristic MAP estimation for tensile damage diagnosis of high - strength aluminum alloy[J]. Engineering Failure Analysis, 2022, 136: 105997.

4. Ai Y, Zhang W, Huang S, et al. A Cross - layer Energy Control Strategy for Indoor Wireless Meter Reading Systems[J]. Ad - hoc & sensor wireless networks, 2022, 53(1 - 2): 29 - 57.

5. Zhang T, Ai Y, Tian K, Zhou J, Zhang W. “A fast temperature rise identification method based on an adaptive particle filter”. International Journal of Advanced Manufacturing Technology, 2018(1-4):1-19.

6. Sun C , Ai Y , Wang S , et al. Mask-guided SSD for small-object detection[J]. Applied Intelligence, 2021, 51(20):1-12.

7. Xie Z, Ai Y, Zhang W, et al. Deep Recurrent Neural Network Architecture of High Order lndirect lntegration Method[J]. Neural Processing Letters, 2022, 54:1233–1253.

8. Wang F, Ai Y, Zhang Weidong. Detection of early dangerous state in deep water of indoor swimming pool based on surveillance video. Signal, Image and Video Processing, 2022,16: 29–37.

9. Zhang T, Liu J, Ai Y, Zhang W. Multi-layer additive tensor decomposition of infrared video for titanium alloy tensile testing[J]. Engineering Applications of Artificial Intelligence, 2023, 124: 106552.

10. Ma H, Wang H, Geng M, Ai Y, Zhang W, Zheng W. A new hybrid approach model for predicting burst pressure of corroded pipelines of gas and oil. Engineering Failure Analysis, 2023,149: 107248

1. "A kind of experimental platform for ac electric power steering system ", patent number: ZL200910241275.3, authorized;

2. "A kind of electric power steering system control model", patent number: ZL 200910237520.3, authorized;

3. "A kind of electric power steering system based on information fusion expert system control method", patent number: ZL 200910237521.8, authorized;

4. "A new type of intelligent telephone alarm", patent number: ZL02203547.8, authorized;

5. “Automatic detection device of electric power bicycle ", patent number: ZL01201843.0, authorized;

6. “An adaptive ultrasonic pulse excitation device and its control method”, patent number: ZL 201410195593.1, authorized;

7. “An internal defect evolution detection and analysis method for metal casting fatigue process”, patent number: ZL 201510009344.3, authorized;

8. “A kind of metal material fatigue loading test and fatigue damage analysis of nondestructive testing (NDT) methods”, patent number: ZL 201510059474.8, authorized.

2024, The First Prize of the Digital Science and Technology Progress Award of the Xinjiang Uygur Autonomous Region

2024, The Second Prize of Science and Technology Award of the Machinery Industry

2013, Third Class Prizes of Beijing Scientific and Technological Progress Award

2009, Beijing Science and Technology Rising Star

2009, Golden Medal for the Top 10 Outstanding Young People in Beijing

Member of INFORMS, TMS and Chinese Society for Metals (CSM)

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026